Book Appointment Now

How to Choose the Right Alumina Balls Based on Alumina Content

How to Choose the Right Alumina Balls Based on Alumina Content

Alumina balls are a crucial component in various industrial processes, particularly in grinding, milling, and chemical applications. However, not all alumina balls are created equal. The percentage of alumina content in these balls can significantly impact their performance, durability, and cost-effectiveness. In this guide, we’ll explore the different types of alumina balls available, ranging from 95% to 68% alumina content, and discuss how to choose the right one for your specific needs.

1. 95% Alumina Balls: For the Most Demanding Applications

Description:

95% alumina balls are the highest purity option available. These balls are designed for the most demanding applications where maximum performance and durability are required. The high alumina content ensures that these balls are highly resistant to wear, corrosion, and chemical degradation, making them ideal for environments that require stringent material standards.

Best Suited For:

- High-intensity grinding processes

- Industries that require minimal contamination, such as pharmaceuticals and ceramics

- Applications involving extreme temperatures or corrosive environments

Advantages:

- Superior durability and wear resistance

- Excellent chemical inertness

- Ideal for long-term, high-performance applications

2. 92% Alumina Balls: Balancing Performance and Durability

Description:

With 92% alumina content, these balls offer an excellent balance of performance and durability. They are slightly less pure than the 95% balls but still provide high wear resistance and chemical stability. These balls are a popular choice for industries that need reliable performance without the premium cost associated with higher-purity options.

Best Suited For:

- General-purpose grinding and milling

- Chemical processing

- Medium-intensity industrial applications

Advantages:

- High durability with slightly lower cost

- Good resistance to chemical and thermal degradation

- Suitable for a wide range of applications

3. 80% Alumina Balls: Cost-Efficient and Effective

Description:

80% alumina balls strike a balance between cost and efficiency. These balls are designed to provide reliable performance at a lower cost, making them an economical choice for many industrial processes. While they may not offer the same level of purity and durability as higher-content alumina balls, they are still highly effective for many applications.

Best Suited For:

- Cost-sensitive applications

- General industrial grinding

- Processes where extreme purity is not critical

Advantages:

- Cost-effective without compromising too much on performance

- Adequate durability for most applications

- Suitable for large-scale processing

4. 75% Alumina Balls: Reliable for Diverse Needs

Description:

With 75% alumina content, these balls are reliable for a variety of grinding and milling needs. They provide a good balance of performance and cost, making them a versatile choice for many industries. While they may not be as durable as higher-content options, they are still capable of handling a wide range of applications effectively.

Best Suited For:

- General-purpose grinding

- Applications where cost is a significant factor

- Industries that require a balance between performance and affordability

Advantages:

- Affordable and versatile

- Suitable for a wide range of industrial processes

- Good performance for medium-intensity applications

5. 68% Alumina Balls: Cost-Effective for Bulk Processing

Description:

68% alumina balls are the most cost-effective solution, particularly for bulk processing. These balls are designed for industries where large quantities of grinding media are needed, and cost efficiency is paramount. While they offer lower durability and wear resistance compared to higher alumina content balls, they are still a viable option for less demanding applications.

Best Suited For:

- Large-scale grinding operations

- Applications where cost is a major consideration

- Processes with lower intensity or where frequent replacement is feasible

Advantages:

- Highly economical for bulk processing

- Suitable for low to medium-intensity grinding

- Ideal for industries with budget constraints

Conclusion: Selecting the Right Alumina Ball

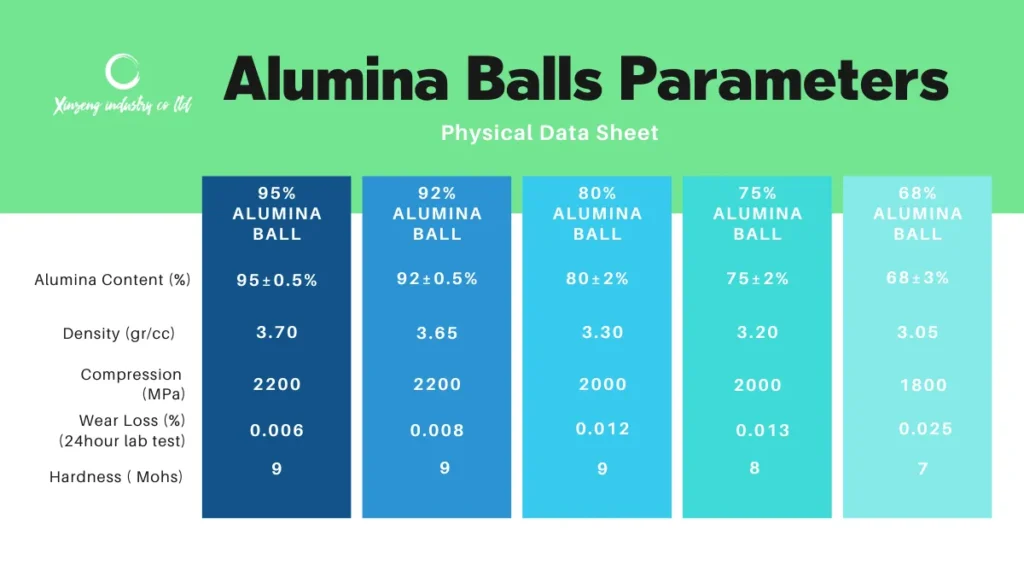

When selecting alumina balls, it’s essential to consider the specific requirements of your application. High-alumina-content balls, such as 95% and 92%, are ideal for demanding environments where durability and chemical resistance are crucial. For more general applications, 80% or 75% alumina balls offer a good balance between performance and cost. Finally, 68% alumina balls are perfect for bulk processing where cost efficiency is the primary concern.

By understanding the strengths and limitations of each type, you can choose the right alumina ball that meets your needs while optimizing your operational costs and efficiency.